Red Team!

Technical Review!

Presentation Video

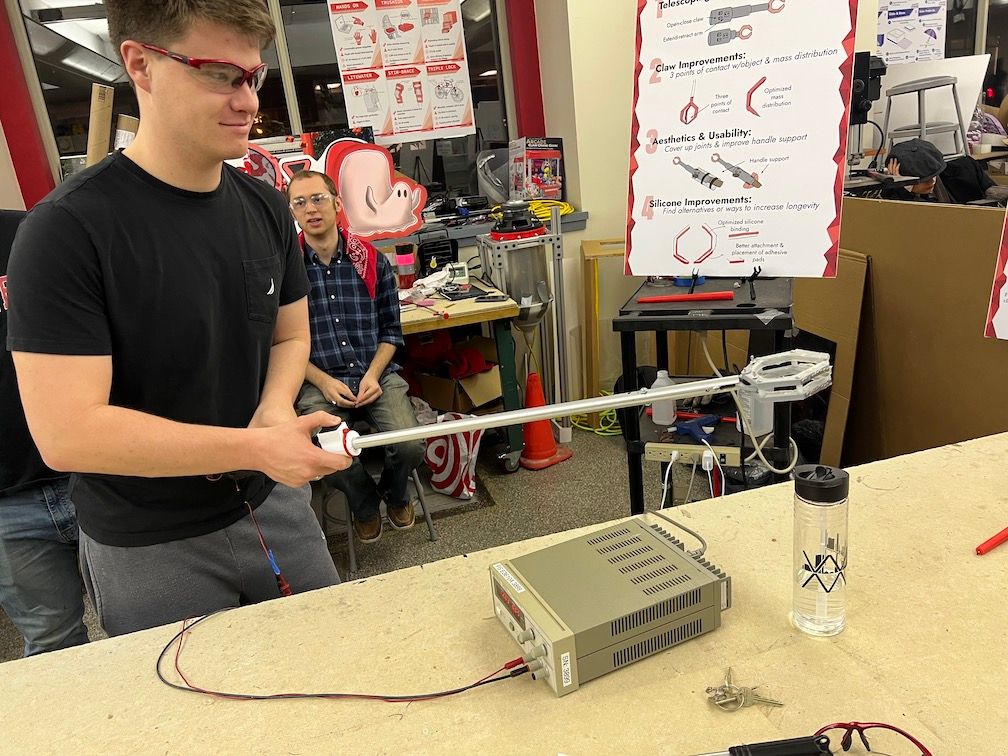

Reach-EZ

An electronic, handheld gripper for those that find issue with the stability & strength requirements of traditional grippers

Product Contract

View Product Contract in New WindowPhotos

Reviewer Feedback

Dave Custer

Feedback

Hi Red Team, Kudos on the re-visioning of your concept. The power assist makes so much sense for your target users and separates your product from others I’m familiar with. Can you use 18650 lithium ion batteries? Pretty good energy density relative to alkaline; recharging rather than replacing seems like it might be easier for people who would have actuation problems. It sounds like you’ve figured out a motor switch + wormdrive friction method to keep the motor from drawing current when the grips are open. There might be other, simple methods, perhaps a ratcheting mechanism like that of forceps. Are your magnets laid out in a Halbach array? If not, maybe you’ll be able to achieve higher forces or lower cost & weight. The ergonomics of the handle grip seems like a thing that could be optimized for your users. When we played with the widget on the table, the ergonomics were different from those of picking things up off the floor from a sitting/standing position. Nice work. Best, Dave Custer

JG Brisson

Feedback

The next two weeks will be a balancing act between your aspirations and what the group can be physically done before the final presentation. Identify what are the key features for the target user and concentrate on doing those key things very well. It is better to do that than concentrate on doing many things (adding features) in a mediocre way. The weight of the device is a concern, particularly when you are targeting users that do not have the use of the second hand (you said that the user would be using only one hand). The length of the device will be limited by the maximum weight you are anticipating to lift. A device that is built to remove an object from the (distant) "third shelf" will not be appropriate to lift a filled one or two liter bottle. You should probably think about the spec on how much torque your user can deliver to your device when using it and scale its capabilities (and weight to that. For example, your user probably can't use (one-handed) a 1 m long device to pick up a full one liter (or two liter) bottle. Certainly the "third shelf" ?two? meter device can even less, given our user's abilities. With weight as a concern, and given user constraints, it makes no sense to build a device to lift (as an example) a full two-liter bottle at the end of a 1 meter long device. I am not sure if you did this, but a real inventory of the lifts a typical user would have to do would be helpful in sizing (both length, robustness, and hence, weight) your device. The device probably should not be able to do all the suggested lifts on that list but should be targeted to do many of them. This is a tool and like all tools, it needs to be sized to the job (and the jobs it will do must be limited). For example, you do not use a sledge hammer to drive tacks. Your gripper seemed fairly robust, but it may be over-designed and hence heavier than need be. Think about the user and what his/ or her limits are, they are probably not yours. For example, mobile older people that are far healthier than what (I think) your target user is, have trouble handling heavy dutch oven pots. They have trouble generating the torques required when handling these heavy pots. (I am not suggesting that your gripper would ever handle a dutch oven. Only that older folk do not have the strength in the wrists that a long gripper requires. Be careful of assuming your user has the strength in the wrists that you currently have.) The idea of a gauntlet to help support the user wrist is a good one but may be an additional accessory that just lays in the box; never to be utilized because the user can't be bothered to mess with it for some single "heavy lift". User research is needed here. I am not sure the improvement in performance of the device with the gauntlet is worth the effort or bother to the user. Although the siren's call of a telescoping device is alluring, I am not sure you should sail those waters. Unless you have a well developed and tested idea, I do not think you have the time to develop the concept before the final presentation. From what I have seen, you seem to have made remarkable progress in the past week. There is still much to do to get this device to what is a "real product". Make sure you use you whole team in the coming two weeks. You will need the efficient work of the entire team to achieve your final goal.

Kamala Grasso

Feedback

Nice job on your prototype. In general, I worry about adding electronics to simple devices but in this case, I think it makes sense and adds real value to the product. I would now caution you about adding additional complexity (e..g. telescoping shaft). Instead, focus on making this device as user friendly as possible. My biggest concern is around the long moment arm of the device. Even for someone with decent wrist strength, it is difficult to pick up a full bottle. For many of your target users, I think it will be impossible. I know you mentioned including some sort of wrist brace with the product. This will take some thought to execute well. You also need to think about the use case of lifting something off a shelf - you may find that this is not something you want to advocate a user do. I can easily see some dangerous scenarios of grabbing something about their head and then having the user not be able to sufficiently control the gripper. You have a lot of refinement to do in the next few weeks but I think you are on the right path - and have come quite far in the last week.

Mitch Guillaume

Feedback

Great job defining your problem - it is clear you have done a lot of user testing and understand the problem you are trying to solve for your customers. Your presentation overall was pretty good, and I liked that I was able to use the product myself without any explanation or instruction from your team. A good product speaks for itself, and this one did. I have a few questions that I would like you to consider- Battery & Energy - You clearly have put a lot of thought into the required energy storage and how it relates to the clamping force. (I liked your plots, but they should start at zero, and you should collect more data to tighten up your confidence bounds) Is it better to have a longer lasting battery and less clamping force, or would it make sense to have a higher clamping force in exchange for a shorter battery life? Clamping Force - What do you do if the object you are trying to lift requires more clamping force than the spring can provide? Is it worth making the motor also contribute to the clamping force if necessary? Fit and Finish - Overall this is a very good looking product. I think that this could be made presentation ready simply by making a final round of printed parts that includes recesses for the magnets and silicon, and better integrates the switch into the handle. Beyond that, sanding and painting go a long way. Extra features - I think your product is nearly ready for the final demo. I would spend the rest of the time cleaning it up aesthetically, and focusing on the details like making sure the magnets are properly attached and the silicone is easily cleanable. If you feel an arm or shoulder brace is an easy addition that adds lots of value, that might be worth exploring, but I would be VERY weary of adding lots of complex features to an otherwise stable product with such little time left. I think telescoping is a complex feature with unclear benefit, as it seems like it could add lots of weight and only be useful for the edge case of airline travel.

Charlotte Folinus

Feedback

Hi red! From my understanding at tech review, you have a functional, working prototype (go you!) and many ideas about how best to use your remaining time. As you choose how to spend that time, I encourage you not to try to be all things to all people — your device can be excellent at a few types of grasping tasks, be very well-executed, and potentially still provide significant value to your target users. It’s tempting to say a prototype or product will be better if you add this feature or that feature — if you’re choosing to add features, it should be grounded in key needs that your users have that your current product vision cannot accomplish. I encourage you to focus on delivering well at the most core needs before adding new features. Two things that come to mind for me are sizing/ergonomics and the polish of your prototype. Sizing/ergonomics: both John and Kamala have left thoughtful comments on this topic. Keep thinking about what size/weight distribution/etc. your users need the device to have -- you can tell a compelling story about not just what the device does, but why it is the size/shape that it is. Prototype embodiment: the goal for final presentations is an alpha prototype, something that looks and works like your final product, even if parts may be manufactured using different processes than they would in production. Attention to small details here will go a long way in creating a believable alpha prototype (provided you’ve met other core needs). Something I didn’t hear about at tech review was how long you want the overall device to last (separate from adhesive or battery life) — but presumably you want it to hold up for a while in actual use, with users who are less careful with the prototype than you. More attention to the details of how the silicone and magnets are attached can help create something that does this (when I came by tech review, you were hot gluing on the silicone, and it looked like at least one magnet had fallen off). For the magnets: what about small recesses for the batteries (press fit, with a dab of epoxy in the back) help them stay secure? If you’re careful with timing a print (and want it to be 3D printed), you could also create a captured/embedded magnet (similar functionality to insert molding with magnets in an injection molded part). For the silicone: are there ways to secure it other than adhesion with epoxy or hot melt adhesive? Even if the main bonding is with adhesion, perhaps covering the sides/corners or using a recess could help protect your corners/edges from ripping and peeling (. If you use adhesion, I recommend using something like Sil-Poxy (https://www.smooth-on.com/products/sil-poxy/ — you’d need certain material compatibility with the gripper side, but the adhesive is more flexible than hot melt adhesive). I also encourage you to consider not 3D printing the gripper part — could something like casting a rigid/semi-rigid urethane or silicone rubber work? You could then attach the silicone using something like Sil-Poxy (easy if materials are compatible) or even mold it using something like mechanical interlocking features (a bit more complex). Casting could also allow you to embed magnets.

Samuel Gollob

Feedback

Overall, great prototype. I liked that you put the electronics all successfully on-board and made the product successful at grasping some difficult objects. I would echo other reviewers: make the handle more ergonomic and hone-in on important features for your user (someone with limited grip strength and dexterity). -Does the handle need to be a constant diameter the whole way? Is there a better handle shape and angle of attack? -Incorporating wrist brace is good focus. -The current switch layout is a bit tricky to operate if you have poor dexterity and especially because you have to time your release - a "hold" position where the gripper neither opened nor closed would be good. -Speeding up the overall motion is a nice to have that would add a lot to the "finality" of product. -Where and how will this product be better than asking someone for help, making multiple attempts on your own, or just using a manual gripper with lower grip force? How does the product's use case make it worth carrying around or going to get it over these alternatives? Making a clear and compelling use scenario is something you guys should polish up. -Realistically, the way this product is carried is also relevant if we're talking about a use with low grip strength and whether they use it in or out of the house. If out, then I'd think about combining as a cane or having a convenient and safe way of carrying it.

Atissa Banuazizi

Feedback

Terrific progress, Red Team! You did a good job identifying and presenting the critical issues for this review. It appears that right now you are trying to optimize for two functions -- gripping and reaching -- that you may not really be able to balance fully. You've clearly stated that your users' lack of grip strength is the key problem you're trying to solve, and that's a perfectly reasonable focus! It's great, of course, that you are aware of the difficulty your users may have bending down, but getting objects off high shelves for a wheelchair user might just be out of scope for this version of the product. (I would be curious about how often your users really do try to use existing grippers for that purpose.) If you made the handle just long enough to get the items they most frequently need to access, you'd reduce the risk of them dropping a heavy object from above (and you wouldn't need to worry so much about telescoping for now).

Ellen Roche

Feedback

Hi Red! I tried to summarize some of the staff discussions and my take on things here. I hope this format is helpful and saves you some time. We are here for you for whatever you need in the next 13 days :) ● Keep it simple! ● Shorten device to prevent wrist injury ● Prioritize what you want to do and do that well ● Lower power - shouldn't draw as much power ● Try to make it lighter ● Attach to the forearm for increased stability. - Jeff Senez (industrial designer) had some great feedback here). He would like to zoom with you Wed night