Purple Team!

Technical Review!

Presentation Video

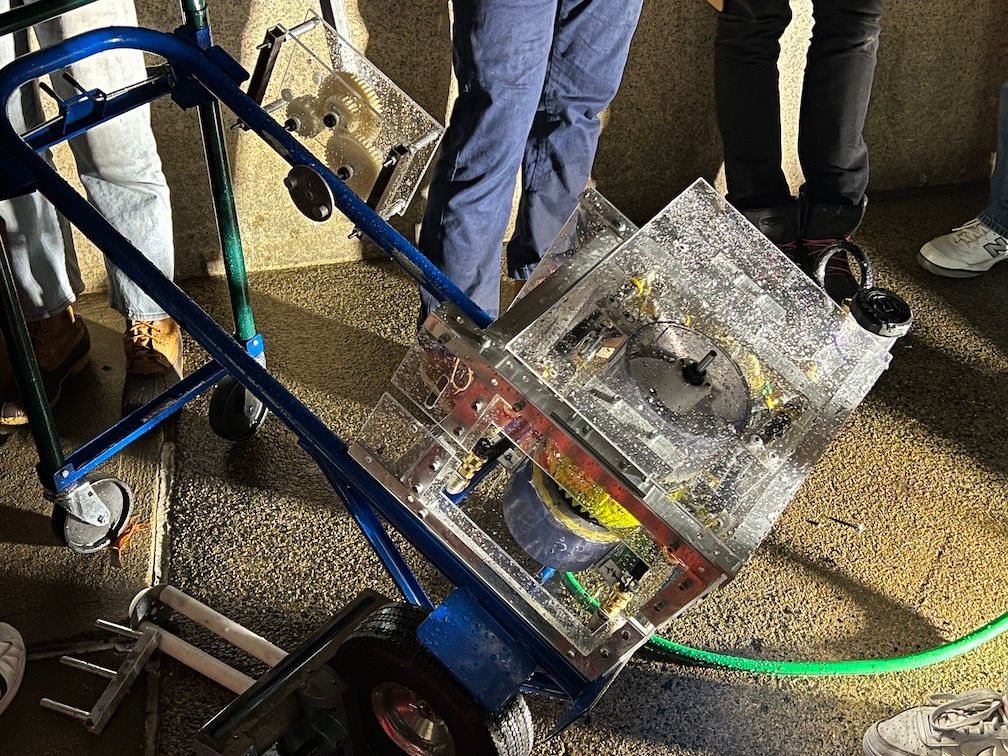

Firehose Cleaner

The Firehose cleaner scrubs and washes away burned debris on used fire hoses, reducing firefighter exposure to carcinogens.

Product Contract

View Product Contract in New WindowPhotos

Reviewer Feedback

Liz Stevens

Feedback

How exactly do the rotating sponges work? It's not intuitive to me that this design is the best for getting a hose clean. When they spin, do they move the hose around? I'm curious whether this is a common design used in other cleaning machines. Was it inspired by a design from a different type of product?

Rob Podoloff

Feedback

Assuming your system will be operated using the very high pressure from the firetruck or a hydrant, I wonder whether you even need the active scrub brushes. It might be sufficient to just have a static brush to knock off the larger debris and then let the water pressure to the rest. Just a thought...

Peter Nielsen

Feedback

Hello Purple Team, good job realizing a first real working iteration of your device. I think the overall size of the device may compromise the cleaning; it is much bigger than the payload - the hose - so a lot of the spray might be wasted. It’s easy to imagine a close-fitting box that the hose passes through doing a more concentrated job of cleaning. It also seems that if the brush is coupled with the water exiting the turbines then no additional nozzles might be needed, and water (everything, actually) always follows the path of least resistance, so the nozzles are compromising the turbine power in any case. The team might consider buying some OTS products like https://www.homedepot.com/p/RYOBI-Rotating-Wash-Brush-Brush-Kit-RY31092TLD/314278366#overlay and dissecting what makes them work. When the hoses are stored on spools in the firehouse is there a standard core that they are rolled onto, and can that be compatible with your spool? In a best case your spool might become the standard for firehouses using your system, with a wall rack that simply accepts your cores. As discussed at review the removable outer spool “key” may be superfluous, a “U” in the right orientation on the frame might suffice to enable the user to simply lift the spool out when done. What kind of lights do firefighters use on site? Whatever that is an interface to the lights will add value for night retrieval. 160gal/min at 100psi sounds like monstrous overkill - it seems probably that a fraction of the flow rate (at least) can be made to do the job. So, smaller, simpler, more efficient, and run every step past firefighters if possible. Solid job so far!

Nathan Phipps

Feedback

Hello Purple! Great work so far, loved seeing your model in action. I'm going to pile on with Rob and Peter and ask if you can do more with less. Using less water and being very particular about how you use it. Imagining blasting a high pressure fan at a low angle relative to the hose may do more work than the brushes themselves. Have you explored this at all? Could do quickly with a pressure washer and there may be some ideal angle. This may remove some of the cool features of the water driven brushes but bear in mind that the best solution is the simplest and you will have plenty of work in productization and design for manufacture. In terms of productization i would imagine that a compact device would be paramount, as everything has to go on a truck. Could you minimize the frame as well? there are certainly some design challenges there given the size/weight of the hose bundle. Perhaps there could be a hinge in the frame to accomodate this? Can the firefighter stand on a plate attached to the frame for weight/balance of the device while cranking?

Keith Clavin

Feedback

Great job getting a working prototype together! I think it looks cool and like a product that would be fun to use. A few thoughts from the review: How will the housing be altered? It seemed to be leaking water at a few points and I wasn't sure if that was by design or just because the housing was still in-process. Also, I know the brushed have been questioned a few times, but they may be more appreciated with dirt or material that is harder to scrub off. As it is, the dirt used in the demo was not baked onto the surface of the hose as it might be in a real-world setting, so maybe finding a way to replicate that would make the brushes more impactful. Is that a full-sized hose that was being run through it at tech review? I envision a fire hose to be a bit bulkier and heavier (plus obviously longer), so some commentary as to how to spool a larger hose would be helpful--it seems like balance or capacity could be an issue in the current model. Also, I received a few different responses from members of the team as to what happens to the carcinogenic material after it is rinsed off--this is something that will definitely be asked at the final presentation, so you probably want to have a definitive response for the team as a whole.

Samuel Gollob

Feedback

It looks like a self-standing product, so good job with that! When I came by, however, almost every subsystem failed (the brushes didn't spin, the hose kept misaligning, the crank detached, etc.). It will take coordiation using your whole team's resources to get it all working, but you're on the right track and can definitely do it! I suggest focusing on the required subsystem functions for cleaning and breaking up your team accordingly (installing hose, pulling hose along, aligning hose, wetting, cleaning, etc.). Make sure some people are always aware of the whole process of cleaning and how the subsystems will play into it. Echoing others, choose how clean you want the hose and do the simplest thing (least moving parts, least spots for failure) that will do it. Have a sense you guys have more moving parts, tubes, etc than you need. General thoughts/echoing other reviewers: - Test with dirty hose, figure out the minimum you need to clean it. Knowing the simplest cleaning target (if don't know already) is definitely worth a few hours of quick tests. - Not convinced brushes as-is are working. Either leverage high pressure or rely on lower water pressure and more intentional brush design. - If you do rely on high water pressure, then buy a pressure washer and use that for testing. - Lots of excess water shooting out - water wasted from cleaning, messier overall, more risk of getting dirt on firefighters. Can there be a tighter design or at least better shielding in the outer shell? - The misaligning hose was an oversight to me. Will a firefighter have to constantly feed the dirty hose with their hands? I would spend time designing an inlet or other feeding mechanism that can align the hose given some range. - Make sure it works first, worry about aesthetics later, can look good with some thermoformed shells etc. if time is tight.

Lauren Futami

Feedback

Hi Purple Team! Thanks for a great Tech Review and firehose cleaner demonstration! Even though the entire prototype wasn't quite working as intended when we saw it, we could definitely see the intention behind the team's design. There was a lot of water spraying out of a few places on the prototype, was this as intended, or is the team planning on reducing this? I remember the team mentioning that firefighters don't mind getting messy when cleaning their equipment, so I just wasn't sure whether or not the spraying water was intentional. I also wanted to inquire more about the existing cleaning process of the firehose - I remember the team explaining that firefighters currently unroll the firehose and hose it down while brushing it out and then hanging it up to dry. The process sounded pretty time intensive, especially because they want to keep their hoses pretty clean, and I was wondering if the team's user requirement could be relaxed a little because of the current cleaning process. It seemed like the team was aiming for being able to clean each hose in under 10 minutes. It sounds like it already takes current firefighters a lot longer than 10 minutes/hose to wash their hoses, and the team might be able to increase this time to even maybe 20 mins/hose, which could give the team more freedom in exploring different ways to clean the hose without relying on highly pressured water (though the current method looks promising and I'm not sure what other methods you've already tried and ruled out). Best of luck with this final stretch!

Ellen Roche

Feedback

Hi Purple! I tried to summarize some of the staff discussions and my take on things here. I hope this format is helpful and saves you some time. We are here for you for whatever you need in the next 13 days :) You likely have integrated a lot of this. already. ● Do you need active brushes? Would static brush work OK? ● Some spray may be wasted (downsize) ● Explore larger shafts ● Simplify outer spool key ● Think about allowing longer time without relying on high pressure water ● Make this work with a garden hose! ● The hose should be guided into the track and stay on track - think about failure modes that would delay use.