Pink Team!

Technical Review!

Presentation Video

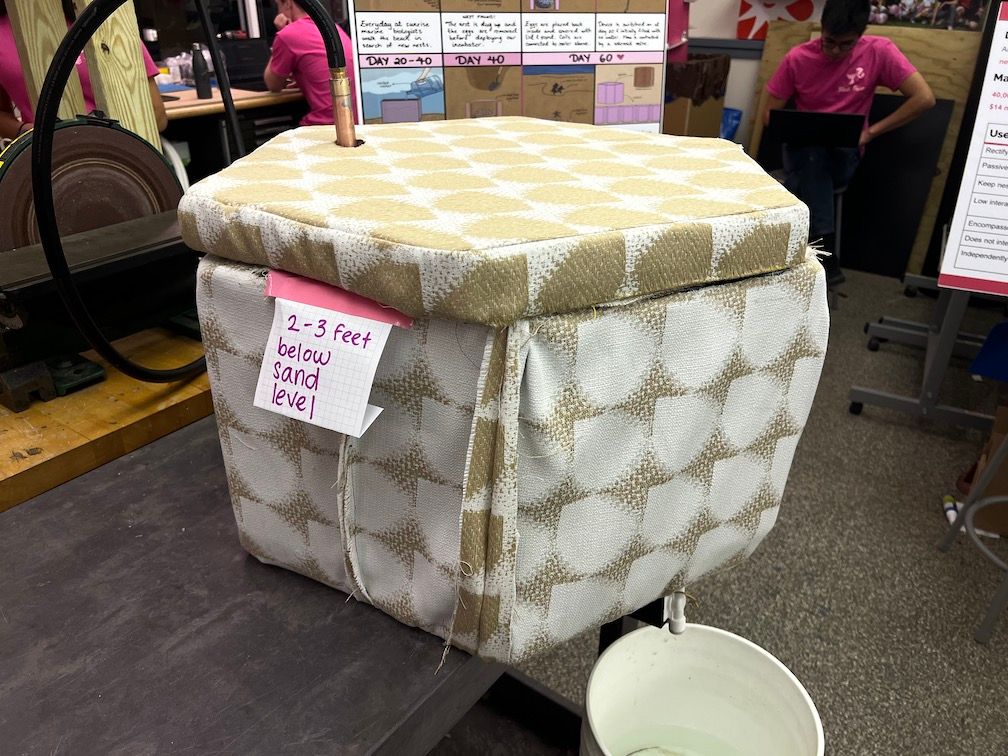

Ashore

An incubator deployed on the beach that cools sea turtle nests through passive cooling

Product Contract

View Product Contract in New WindowPhotos

Reviewer Feedback

Chuck Xia

Feedback

The current model have three components, the electronic box, cooler, and incubator. Would combining the electronic box with the cooler (above the sand) or the incubator (below the sand) make the system simpler to use? We briefly discussed moisture/humidity. If it is going to have an impact on the health or mortality of the eggs, it would be worth while to understand why, how, and what is the trade off. Would you be able to use passive constant flow valve (I am not sure if it meets the spec, for example: https://www.usplastic.com/catalog/item.aspx?itemid=124388&v1=&v7=&gclid=Cj0KCQiA4OybBhCzARIsAIcfn9n41p0aMu8GND4RN_kekpe6uACOnEPFDdgqpuyqAwQNuMrmMS7Eu6kaAm-aEALw_wcB). That could eliminate the electronics below the sand. You all already selected a marine fabric to cover the insulation. There are also a lot construction material that are both insulating and waterproofing, maybe some could be useful.

Dave Custer

Feedback

Hi Pink Team, A nice, simple design. Can you make it even more simple for your turtle biologists? For instance, can you use a garden hose instead of copper tubing? Maybe your “product” is a DIY turtle saving kit plan that shows people how to use home depot supplies to keep turtle eggs cool? There was some talk during the demo about being able to omit the electronics; I’m guessing that would be beneficial on a number of fronts, e.g. reliability, cost, vandalism… Can you omit the temperature control valve and instead use a pinhole that allows the water flow through the system at a constant rate? One major concern I have is the drainage of the water. How will you be sure it doesn’t lead to oversaturation of the sand around the turtle eggs? How will you be sure that the water will drain away into the sand at a rate that permits adequate cooling of the nest? Does the ocean’s water table put limits on the flow of your cooling fluid? If you’re using fresh water, will it “float” on salt water? A point of curiosity: how much water pressure do you need to make this work? Does the cooler need to be up on stilts? On the beach surface? Can it be countersunk into the sand? The lower the necessary water pressure, I’m guessing the system can perform better—lower cost, water stays colder longer, less vandalism… If you can bury the cooler in the sand next to the eggs, when the cooler heats up, you are essentially cooling the sand in the vicinity of the nest, even if the cooler water is not symmetrically wrapped around the nest; that sounds better than just losing the cool via air conduction and radiation. Best, Dave Custer

JG Brisson

Feedback

I have been intrigued by the work your group has been doing since the first time you presented it to the class. In addition, it is clear that you have had many dialogs with researchers in the field. Some comments on design philosophy. I have seen you move from what I thought was a fairly complicated design (active refrigeration, electrical systems, fairly sophisticated computer control etc) to a simpler system that periodically fills a chilled water bath in pipes that surround the nest with some kind of sensor/timing circuit that periodically allows cold water into the pipe jacket while discharging the spent water. My compliments on seeking a simple solution. Simpler solutions usually have fewer failure modes and hence is in general the more robust solutions. On your design: I believe the burying of the discharge valve in the sand is a weakness. It is likely that some sand will get into the valve and jam its operation rendering your system in operable. In addition the flow conditions at depth are uncertain. For example, it is possible that the impedance to flow at depth could significantly change the flow conditions at the valve, reducing the discharge rate to an unacceptable level. The valve could be left above the sand level to discharge water onto the surface. I recognize that you have focused a great deal of thought on this problem, but Is it possible to find simpler, passive designs that achieve your goals? The electronic control and monitoring would be needed to validate a passive design. But once that design is validated, it would be less maintenance and more robust that the more sophisticated electronic approach. The electronic approach is appropriate when passive designs can't be found or if the user requires a constant direct monitoring of the clutch temperature (perhaps a cell phone connections back to the laboratory). I don't think direct monitoring is in your product contract. Could the coils in the sand just made large enough so that ice water could be directly poured into them to maintain temperature for a week? This would eliminate the "Yeti" on the surface of the sand; but still maintain your researcher carrying out ice to the site on a weekly basis. This could eliminate your electronics requirement. I am not sure what volume and how deep the pipes would have to be with this design. You have established that digging up the turtle eggs once (when they are "young") and that leaving "Yeti" ice chests on the beach is an acceptable practice. Why can't you simple put the clutch and sand in one compartment of a yeti cooler with Ice thermally linked in another compartment? The researcher would then empty and refill the ice compartment every few days. In general, to get the five day time with ice in the cooler, the cooler must be one of the larger versions. (Surface area (parasitic thermal load) to volume (stored "coolth") ratio works in your favor as the size of the cooler increases. ) The design would have to provide a (presumably small) thermal link to the outside world to keep the eggs from cooling all the way to 0 C. Are there phase change materials that "melt" at temperatures near the male turtle temperature that can be used in the other chamber of the Yeti cooler? A higher melting temperature than that of water would reduce the heat leak into the cooler and if the latent heat is reasonable, extend the lifetime between refilling of the refrigerant into the Yeti cooler. This autonomous cooler approach would allow the entire system to be built off the beach and carried into where it is needed. Much of its volume would then be filled with sand, making it very hard to steal (it weighs a lot). Presumably it could be closed and locked to limit the effect of poaching. (Your arguments that the general populous is supportive of the turtles is probably true in affluent areas of Florida; however, I believe turtle eggs are actively sought after and dug up for food in less affluent regions of the world.) You will probably need to allow the changing of the air inside the cooler periodically which will, unfortunately, reduce the time between ice loadings. In addition, a large cooler could accommodate several clutches of eggs. When it comes to hatching time, the lid can be removed and ramps placed along side the cooler. If you don't think the researchers are getting enough exercise, or you just don't like the urban blight of coolers everywhere, you can bury them, up to the lid.

Kamala Grasso

Feedback

I like how you have significantly simplified your design - it increases reliaibility and reduces cost. A win-win. The idea of a cooler sitting on the beach is a bit worrisome although I know that you said the general population generally stays away from nests. I like to think that is true but imagine it is not in all locations. And even if bystadners leave them alone, a bunch of plastic coolers sitting on a beach isn't an ideal view. I wonder about the ability to re-use the insulation multiple times, I would think that sand and moisture would take its toll. You definitely don't want the insulation breaking down and contaminating the area with small particles. Overall, it's an intriguing product concept and worthy cause and I look forward to seeing the final version.

Rob Podoloff

Feedback

I like the progress you have made and the way you have simplified your design. I wonder if you could make it even simpler by adopting a pan within a pan design (like a pressure cooker). You essentially leave a space between the two pans and fill that with your ice water (instead of pumping it thru a coil). I also think there may be a way to use a purely mechanical system (using a bi-metallic control valve) and save having to have a battery and electronics.

Mitch Guillaume

Feedback

It seems like you've done a good bit of research and you understand the requirements for the turtle eggs pretty well. I would challenge you to dig deeper into your customers' requirements. Is it going to be easy for your customers to use your product in the field, which is a sandy, salty, beach? Thermodynamics - My understanding of your product is that the coil will be filled with ice water, and then sit there for some period of time until it reaches some temperature threshold, and then the drain valve will open and a new batch of ice water will enter the coil. Is this the most effective way to cool the eggs? My intuition would be that constant, low flow would be more effective / efficient than intermittent, high flow. This would maintain a more constant temperature too, instead of the temperature dropping rapidly when a new batch of ice water is introduced all at once. If you did this, you might even be able to get away without having a valve at the bottom and just let it drip. Durability - I think the biggest thing you could do to improve your product is simply make it more rugged. This thing is going to get dragged out onto the beach and buried for weeks at a time, where it will be sprayed with salt water. Is this going to hold up? Maybe consider making a plastic shell instead of cloth, or using a more rugged canvas/kevlar cloth. Service time - How long will the ice water reservoir last? My guess is this is a huge factor in whether or not your customer will choose to adopt your product. The longer the machine can go unattended, the better I think.

Rebecca Thorndike-Breeze

Feedback

Well done! You’ve made a lot of progress, and this simplified design is really interesting. Given that every day at sunrise, marine biologists walk the beach in search of nests, it seems that this system needs to be highly portable. The current 3-module system still seems too cumbersome for this task. What means or transport have you considered? Can these components be easily stacked on a dolly? Would the biologists run back to their truck once they find a nest and then bring the system out? The time window is short, so having the system at the ready seems essential.

Jordan Tappa

Feedback

I thought your layout for the product architecture was strong, and clearly showed how each section will connect. My biggest concern is that the spout at the bottom is simply buried under the sand with your device. So if you attempt to drain it, I suspect it would saturate the sand around your turtle nest and you won't be able to put fresh, colder water in. Consider draining it out to the ocean or back up to the surface. Sooner than later, you should consider burying something in the sand on the beach for a day or two. Weather-proofing is going to be a large task, not only as engineers but as designer. Right now, the material may seem sturdy, but against the elements will be another story. things like holes in the lid and allowance around the lip of the container will be pain points. When polishing this up for final presentation, consider that the audience needs to believe this is weather proof as well. Right now, it does look a bit like a living room ottoman - rather than a tough, rugged, turtle nest protector.

Ellen Roche

Feedback

Hi Pink! I tried to summarize some of the staff discussions and my take on things here. I hope this format is helpful and saves you some time. We are here for you for whatever you need in the next 13 days :) ● Combine electronic box with water supply or box in sand ● Explore a passive constant flow valve? ● Explore a double jacket design with water in between ● Don’t bury discharge valve in sand - could clog - can you reposition to prevent clogging? ● Potentially move away from electronics once validated ● Could you use coils/double jacket large enough for iced water ● For valve – explore constant low flow vs intermittent high flow Go pink!