Gold Team!

Sketch Models!

View the 4 Presentation Slides (.pdf)

Presentation Video

Concepts

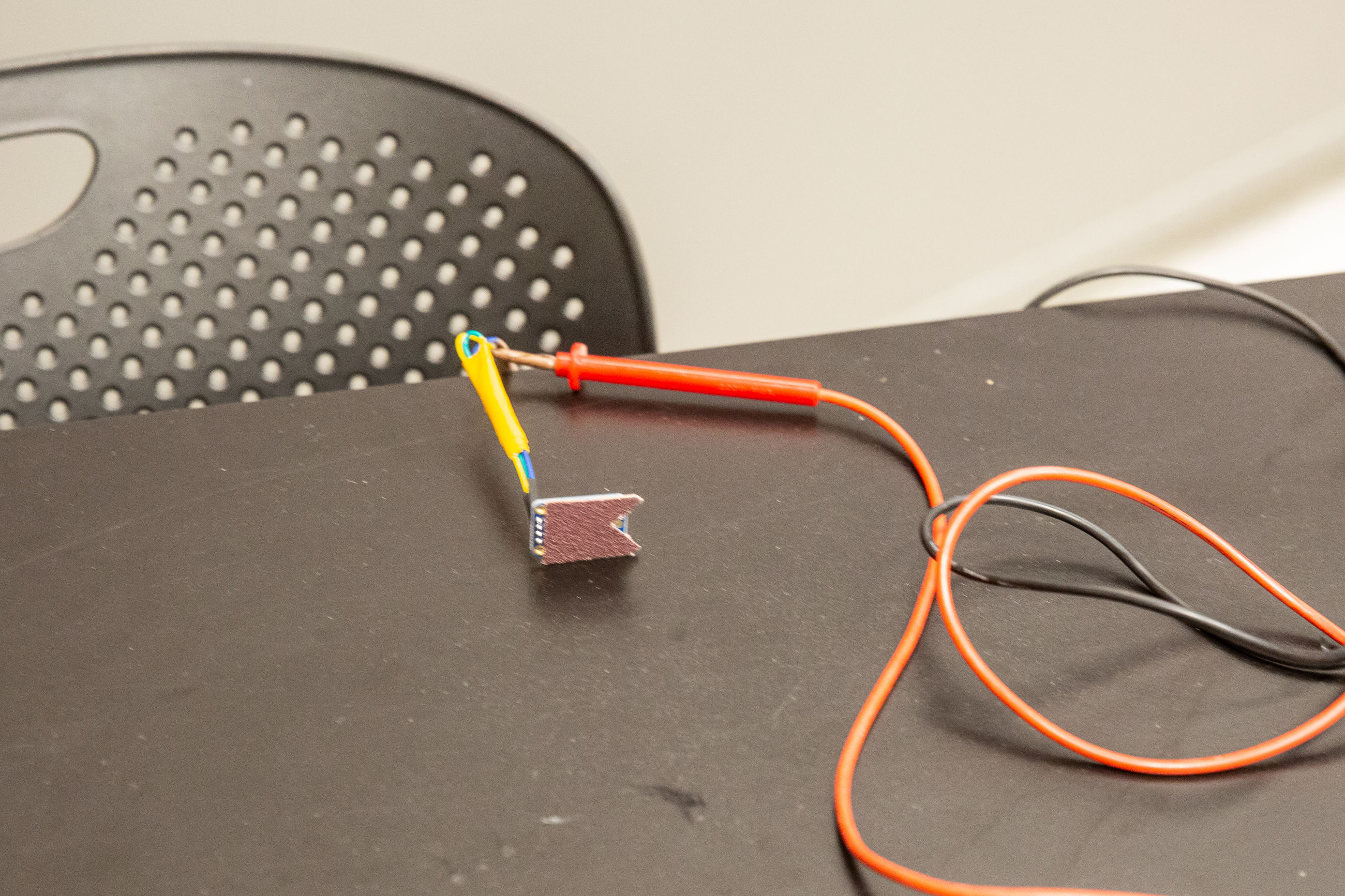

E-Stop Disc Sander

A disc sander that immediately halts rotation when it senses fingers contacting the sandpaper

Reviewer Feedback

Atissa Banuazizi

Product Opportunity

Improving user safety is always compelling! But I would have liked to have heard something about how often injuries with disk sanders occur, or how serious those injuries can be. Stats would have been wonderful, but even anecdotes would have been helpful -- talking to potential users (I have no doubt you have plenty of access to them!) and using some of their stories could really have an impact on your audience.

Product Embodiment

If I understand correctly, it seems like e-stops for sanders do exist but don't work well, and that, apart from the potential of capacitive sensing, your innovation for the product vision (at present) is to clamp the shaft rather than the disk. I didn't get a clear idea of whether (or why) that's preferable, although you could certainly convince me!

Model Learnings

You did a great job of articulating your questions! I do wonder whether "can sense through sandpaper" is the most serious challenge, though.

Model Execution

I think it was terrific that you brought up the force-rotation relationship, although I had no clear sense of where that data came from.

Sam Ihns

Product Opportunity

I'm a very clumsy person and one time accidentally did have my finger brush against a moving disc sander. The rotational force of the sander actually acted to deflect my hand/fling it off of the sander (similar to how a piece of stock may be sent flying if you don't hold onto it well enough). I was scraped but had no serious injuries (although perhaps if I had put any weight into my hand it would have been a different story). I would be interested in seeing some information on how prevalent disc sander injuries are and what they primarily consist of - this could help tailor your design. Another similar danger that may be more common is hair or jewelry being pulled into the machine by operators not following proper safety protocols. Again I'm not sure how prevalent this is and have no data on it, but anecdotally it is an issue as well. Also, this concept may be much more successful as an add-on then as a standalone disc sander. Many of the prime userbase for this product will already own a disc sander, and the sanders themselves are so well-designed on their own that it will be difficult to match their inherent sanding quality. Using an existing sander may also make less work for you all!

Product Embodiment

Capacitive touch sensors can be tricky in that they don't actually require a "touch" to trigger - depending on your limits even approaching the sensor with your finger can trigger it (in your demo it seems like the sensor triggered before a true "touch," is that correct? It may have just been the document camera as well). The limits can be adjusted to fit your needs but variations in sandpapers and human skin will need to be taken into account! False positives with this system may not be harmful (depending on how you choose to stop the wheel) but they will be annoying, especially if the top is triggered every time your finger comes within a centimeter of the disc! To second what Rob wrote, a bigger challenge may be effectively stopping the disc. You mentioned in the presentation a stop time of one revolution - is there any data to back up that this is a feasible stop time? I'm excited to see how the product embodiment evolves!

Model Learnings

While the model demonstrated that you can successfully determine human contact through sandpaper, I wish it showed a bit more that you can tailor the sensor to also not trigger prior to the user touching the sandpaper. On top of this, the more difficult challenge may be figuring out how to stop the disc.

Model Execution

It would have been nice to see a few other potential methods of detecting a human touch, as well as some capacitive touch sensing with various sandpaper brands/thicknesses/hands/gloves to demonstrate applicability to the field!

Adam Frick

Product Opportunity

No feedback provided

Product Embodiment

Would moving the disc away from the user also be viable to prevent injury? It seems like a simpler solution without concerns for braking speed and energy dissipation. This could also be achieved by any sensing technology that could anticipate human contact with the disc.

Model Learnings

I would have liked to hear detail about how the grit and thickness affected capacitance. You've mentioned capacitive sensing being used in a large museum model - as you scale up, what technical challenges will that entail? Being able to distinguish between metal and flesh will be important to figure out too

Model Execution

No feedback provided

Juergen Schoenstein

Product Opportunity

I have every confidence that there is a true need for a device that can stop disk sanders, the way the Sawstop prevents injury on table saws. I could imagine that there is a somewhat higher likelihood for "false positives", because of the variety of materials that will eventually touch the sander - as long as the resetting is not too cumbersome, this might be a small inconvenience, considering the benefits of reducing injuries.

Product Embodiment

I am not sure that I saw an indication of a stopping mechanism - in the Sawstop products, the stopper actually interacts with the teeth on a saw blade, which may damage the blade, but has a high likelihood of actually stopping on the spot; but the mechanism for the disk sander would have to be different. What would be able to accomplish this fast stopping? Or would it be more feasible to, rather than actively stopping the tool, or will move away from the hand (as you indicated in your 3 Ideas Presentation)? The latter might seem to be more attainable...

Model Learnings

You were able to show the working of your sensor - but I felt like this was an easy target, since those sensors have been widely used and are fairly well developed. Just remember that sensing a problem by itself is not solving a problem - it's what you do with the information that the sensor provides.

Model Execution

See my previous comment: You probably knew what the answer was that your sketch model would provide. But yes, trying out is still better than taking anything from literature for granted, and some of the data (of which you hopefully gathered plenty) might be useful if you decide to go forward with this idea. But your focus shpuld then be on the mechanism that will do the required work.

James Penn

Product Opportunity

This seems like a good opportunity. Will it also work if the user is wearing gloves? Perhaps there could be a secondary accident detection method that gets activated when sanding metal, if capacitive sensing doesn't work well for that.

Product Embodiment

No feedback provided

Model Learnings

No feedback provided

Model Execution

No feedback provided

Rob Podoloff

Product Opportunity

One thing I am not completely clear on is how strong a need this really is for a potential user. Unlike a table saw or other cutting device which can easily sever a limb or finger if the user slips, the consequences of a slip into a disc sander does not seem to necessarily merit the same level of protection.

Product Embodiment

Although you concentrated on sensing, I think the real challenge of this concept is how to either stop the spinning disc or how to move the disc away from the user (or the user away from the disc) to save the user from serious harm. I think it will be difficult to slow the disc fast engough to be the only protection method.

Model Learnings

See above. Don't think the model addressed the most important question about the concept

Model Execution

Would like to have heard about what other sensing methods were considered and why capacitive was chosen.

Kaitlyn Becker

Product Opportunity

Gold team - all great presentations - good job practicing and prepping for these. This seems like a fairly clear motivation, though there wasn't a specific user emphasize. This didn't seem like a necessary addition for this particular product as long as not required by the milestone presentation. How many disc sander injuries are there and how serious? Have there been any on campus? I don't normally think of these as super dangerous tools. It might depend on the grit of the sand paper and gap between the disc and the platform in front.

Product Embodiment

This seems like it's on the right track but definitely check how well the capacitance sensing works in different scenarios.

Model Learnings

The energy analysis of breaking and capacitance seemed like good questions to dig into.

Model Execution

You may want to justify whether a destructive or non-destructive braking mechanism is more appropriate based on the frequency of false-positives and potential severity of accidents. If non-destructive, how many times could the braking mechanism be used before it needs to be inspected/serviced/replaced?

Assistive Miter Saw

A miter saw that reduces setup time and increases accuracy and repeatability of cuts via an automatic feeder and servo actuated angle setting

Reviewer Feedback

Atissa Banuazizi

Product Opportunity

There is certainly a huge market, broadly speaking. My difficulty was that I couldn't fully grasp the product vision or use case. How automated do you want to make the process? That is, you clearly say you want to speed things up, but what kind of scale of change are you talking about?

Product Embodiment

see above

Model Learnings

You did a nice job drawing our attention to the questions you wanted to address, but I had some trouble discerning what the model was. For the first part, I think the idea was to measure the accuracy/precision of the measurement tools that are already out there to see if they met industry standards, but it doesn't seem like that was the biggest challenge for making your product work.The second question, actuation, seems very interesting, but I wanted to hear a lot more about your model and how it was tested, in order to get a better sense of how it was answered.

Model Execution

see above

Sam Ihns

Product Opportunity

Focusing in on a particular use case will be very valuable. Contractors, at-home hobbyists, and box stores will all have different needs and constraints. I think this concept could be particularly valuable for box stores like Home Depot. I'm not sure if any of you have experienced this, but most of these stores have a cutting area where you can have an employee chop your boards to size before you leave. It's a really useful thing, but it's such a pain in the ass to have to deal with an employee who is unhappy to be bothered with the task and also may miscut your boards (these have both been common in my experience). If this concept could be scaled up, it could be a great way resource for these stores. It would also free up any cost and space constraints, as these stores are very large and have the capital to invest in a tool like this.

Product Embodiment

I wasn't able to really grasp what embodiment you had for this product. The CAD onscreen seemed to be a standard miter saw with a motor attachment. At this early stage, it's very important that whatever embodiment you choose (for cutting, board measurement, UI, etc) is chosen through a user-centric and data-driven process. Assumptions about how your product should look or operate can force you into design choices that may not be optimal with users! Just something to look out for.

Model Learnings

More testing will certainly be necessary to draw concrete conclusions for your testing. Channel Dr. Hughey's energy - if you are collecting data, try and collect enough to establish statistical significance/some sort of data-driven confirmation you are on the right track! However, it does seem from these preliminary tests that you are able to measure the length of the board within spec. Very promising!

Model Execution

More data will be necessary to confidently determine which method is best for measuring. However, the decision on what method to use may also be driven by user needs (assuming multiple measurement options can all meet the specs you need). Great work!

Adam Frick

Product Opportunity

I am not a miter saw user, so while I see how automation assists with the efficacy of this tool, I wonder if this is the right place for automation in the first place. Do construction site workers find measurement the most tedious or time-consuming aspect of woodworking?

Product Embodiment

No feedback provided

Model Learnings

Focusing on sensor and servo accuracy for the model felt like a good approach.

Model Execution

No feedback provided

Juergen Schoenstein

Product Opportunity

I think that the problem space that you have identified for your product idea is real and relevant: Compound miter cuts are hard to get right the first time, and usually take multiple trials and errors before they are perfect. But I am not sure that you have identified the real problem: The multiple cuts are not because the operator is not skilled enough to set the correct angles - but rather, because those angles are very hard to measure. In the "wild" of a construction/build project, perfect right angles (and perfectly consistent angles) are rare, if not impossible. If I recall correctly, many compound miter cuts are "scribed" (= taken directly from the spot where they will be applied) - but that would not generate the metrics that you would have to enter into your device. I think a more challenging, but also more rewarding path would be to focus on measuring these angles and lengths for perfect miter cuts - once those are established, setting the blade correctly will be fairly simple, even without assistance.

Product Embodiment

I have to be honest: I did not see a vision for a physical product here, just some components that are already available on the market.

Model Learnings

See my first remark on the problem space - this is still something that lies ahead of you, if you want to pursue this idea further.

Model Execution

Well, since I did not see an actual model, I can't answer this question...

James Penn

Product Opportunity

This seems like a good opportunity. Given the scope of the class, it might be good to focus first on reliably automating the process of setting angles and lengths before tackling the more ambitious goals.

Product Embodiment

No feedback provided

Model Learnings

No feedback provided

Model Execution

No feedback provided

Rob Podoloff

Product Opportunity

I found the presentation confusing and was not exactly sure what the proposed product embodiment was. I know it was some kind of semi-automated miter box, but I was unclear how it actual was put together and how it fit into the intended users daily workflow.

Product Embodiment

see above

Model Learnings

not clear

Model Execution

see above

Kaitlyn Becker

Product Opportunity

Gold team - all great presentations - good job practicing and prepping for these. The motivation was more clear in this presentation versus the 6 ideas presentation

Product Embodiment

The sketch model itself wasn't super visible but it sounds like a very tractable problem based on existing products

Model Learnings

Extensive testing? 4 data points? Explain the plot a little more. The plot was also hard to see from the back of the room, perhaps too low resolution of a png to be displayed nicely?

Model Execution

Might have been good to go into more of the potential safety concerns

Nighttime Ocean Rescue Dye

A device to release bioluminescent dye to aid in maritime search and rescue operations at night

Reviewer Feedback

Atissa Banuazizi

Product Opportunity

You made a good case for the need for rescue operations to be able to spot people in the water when nighttime comes!

Product Embodiment

I like the concept of using bioluminescent dyes instead of fluorescent ones. I didn't have a great understanding of the use case until way into the presentation when you finally mentioned life jackets. One question then is: since presumably your users would be using these jackets both day and night, would your bioluminescent dye be as visible in sunlight as the current dye?

Model Learnings

I didn't understand why having the dye stay on the surface would be the biggest risk to address -- wouldn't this issue have been explored with the current dyes? Does the bioluminescent dye need to stay closer to the water surface for visibility? (If so, that wasn't clear from the presentation.)

Model Execution

Obviously you used the body of water you had the best access to, but I imagine that ocean waters might be really different from the Charles.

Sam Ihns

Product Opportunity

The problem you are looking to address is clear - and using chemicals to produce a light source in the water is certainly a novel way to accomplish it! As people float in the water waiting for rescue, they can end up moving many miles due to the current. An LED on a life vest is incredibly effective at pinging a person's exact location, but a slow releasing chemical, that perhaps releases over several hours, could have a unique benefit of leaving a long "crumb trail." this could allow rescuers to find the trail and follow it to the survivor. Here's a cool video on the coast guard's algorithmic search patterns they use to find people in the ocean, accounting for currents: https://www.youtube.com/watch?v=aoXJfuPaFF8

Product Embodiment

For this concept to solidify, you will need to better establish what sort of chemical you would be using and what sort of dispersal method you will be using. It seems like, as this is a meche class, the dispersal unit will be the main focus.

Model Learnings

I'm not too sure what the model answered - naturally oil will float on water, but the oil may not even be reflective of the chemical you would ultimately end up using. An analysis of the drifting pattern of the oil, or how long it remains around the survivor, may have been a way to gain some more information from this.

Model Execution

I think this model may have been a bit lacking in terms of execution, and as a result it may have limited how much you could really learn from it! A bit more of a focus on data collection would have been good, as well as some initial exploration into potential chemical combinations. Also, I'm sure you are hearing this in all your other feedback but perhaps pouring the oil into the Charles was not the best test method, both for ecological reasons and because it does not seem reflective at all of the environment that a rescue would take place in.

Adam Frick

Product Opportunity

No feedback provided

Product Embodiment

I have concern about the necessity of oxygenation for luminescence when the chemicals are stored in a life jacket, since the user may be unconscious or drown without splashing. Turbulence from a capsized boat may be limited. Maybe induce turbulence as a failsafe?

Model Learnings

It's helpful to know dye visibility without luminescence was satisfactory, but had this been known already with existing products?

Model Execution

No feedback provided

Juergen Schoenstein

Product Opportunity

I usually like to say that it is a warrant for the need when there are already products in the market that address what you want to address. My concern here is that I am not sure that your idea (which would, if I understood correctly, will work essentially like the Landfall Fluorescent Dye Marker that you show on your slides) has enough novelty to warrant your efforts. And I did not grasp what the advantages over, let's say, a small electronic beacon or even the blinking lights on existing life vests would be.

Product Embodiment

See my first comment: I did not see how the embodiment for your idea would differ from existing solutions.

Model Learnings

I am not sure what you were trying to answer - or rather, why the question whether you could "release a dye that remains on the surface of the water" would be critical. Seems like that has been proven.

Model Execution

I gasped when I heard that you poured the dye in the Charles River, and I still wish I had not been made an accomplice after the fact. Maybe I am too sensitive about environmental issues, but releasing something that is essentially a bioagent into an already strained environment, without a proper plan and without oversight and review just does not seem to be a good idea. On top of that, the Charles River, with its calm waters, is not even remotely an environment where such a solution would be beneficial: I would expect that the majority of person-over-board events happen in rough seas, and that's the condition where it remaisn top be proven that this approach has merits.

James Penn

Product Opportunity

This seems like a good opportunity and an interesting solution. Would chemiluminescence be a more accurate description than bioluminescence? You have a number of critical questions to answer regarding feasibility of this approach and your "Next Steps" seem like a good starting point; in particular, I imagine you will want to determine ASAP what amount of chemicals and oxygenating activation you need to achieve a given visibility at a given distance for a given duration.

Product Embodiment

No feedback provided

Model Learnings

No feedback provided

Model Execution

No feedback provided

Rob Podoloff

Product Opportunity

Anything that helps people who adrift at sea seems like a good idea to me. I was not really sold on the concept that the bio-luminescent solution was better than a blinking led. Did you do any experiments to see how much light you could generate and for how long? Would the substance to too quickly dissipated in the water to make it effective?

Product Embodiment

Not sure. Depends on answers to above questions

Model Learnings

Don't think you answered the main question

Model Execution

see above

Kaitlyn Becker

Product Opportunity

Gold team - all great presentations - good job practicing and prepping for these. This seems like a great potential application but the implementation was not fully clear. There was an early mention of life vests and I assumed it would be built into a life jacket, which would reduce utility if you don't mange to get that life jacket on. Upon reflection, having this built into a boat makes more sense based on the rest of the presentation. It's possible I missed a brief explanation on this while taking notes, but you can expect that your audience will miss things and a sketch showing how this might be implemented would be helpful. The bioluminescence pictures and floating oil were great but are an incomplete picture of what's going on.

Product Embodiment

No feedback provided

Model Learnings

I think we know that oil can float. What materials do you intend to use and how much light do they put out? For how long does the light last? How far away would this be visible? In what scenarios would it be used and mixed by turbulence? A big boat sinking would be sufficient turbulence but not a kayak. How would the release be triggered?

Model Execution

I think the mixing and visibility are bigger questions than the material floating, though it's important to note if the bioluminescent material you are adding will stay suspended in the oil if that's what you're using to make it float and whether it inhibits the reaction/mixing. Relating to a question asked - while I agree that saving lives is a motivation that allows some flexibility for environmental impact, this is a critical question and all materials considered for their environmental impact. At minimum, perhaps compare this to the impact of the fuel/oil from the boat that this might be implemented on for a comparison.

FloodBox

A collapsible waterproof storage device to protect precious belongings from water damage.

Reviewer Feedback

Atissa Banuazizi

Product Opportunity

I am definitely all in on the idea of flood protection, but I can't quite understand what problem this product concept is designed to solve: that is, why do you need a collapsible *but also rigid* method? Very large heavy-duty plastic watertight bags exist, and so do bins, but can you clarify what *specific* need is not covered between them?

Product Embodiment

see above

Model Learnings

Once again, Gold did a top-notch job of articulating the question you focused on, but I'm just not sure why collapsibility is so important. I was, however, absolutely delighted to see the model in use onstage!

Model Execution

Going back to the product vision for a second: is the idea that the objects you want to protect are *so* big (like what?) that they wouldn't fit in anything you could reasonably buy and store in the home? In that case, your sketch model will really need to scale up a lot, right?

Sam Ihns

Product Opportunity

There is a clear need for better ways to protect items in the case of flooding. The main point of contention I see is differentiating your concept from simply putting the items in a heavy duty trash bag. Another thing that may be of interest - in 2020, one of the teams in 2.s009 created a foldable boat for use in emergency floods as their final product. Perhaps there are some insights you can find by looking at their process/final presentation!

Product Embodiment

The folding mechanism in combination with a waterproof seal may prove more difficult than you expect. It also seems a little bit redundant to have specialized boxes that are only pulled out a few times per year and require time be spent packing and unpacking them. A possible path that could simplify these challenges would be do make the box more permanent and furniture-ey, almost like a shelving unit or something. A user could use it for storage as they would any other piece of furniture and then simply zip it up/close it in the case of a possible flood.

Model Learnings

The biggest questions regarding this concept are waterproofing and user interactions (broadly). Instead of designing a "looks-like" model of the folding box design and then retrofitting waterproofing/user-experience features onto the box, it may be better to gain a broader understanding of what users actually want and will use + solve the technical challenge of sealing the box and then use those learnings to inform what the product will look like.

Model Execution

No feedback provided

Adam Frick

Product Opportunity

No feedback provided

Product Embodiment

Do be specific about what category of items this is intended to protect! Making it collapsible communicates this is for things of large quantity or volume, but does the material limit the weight it can hold (due to disturbances caused by floodwater)? Are you able to target household items for this form factor that people have an immediate need to protect? How would this product be compelling over large plastic containers? (this is what I use for storage in my basement that is prone to flooding)

Model Learnings

No feedback provided

Model Execution

Expanding the box is easy and that was clearly communicated, good! Even if the lid does not provide a watertight seal, how is this anticipated to be achieved?

Juergen Schoenstein

Product Opportunity

We just saw Florida being flooded, and it seems that such climate change-related events will only become more frequent. And the phrase "we have lost everything" was frequently uttered by those victims. So by all means, there is a real and urgent problem, and working toward a solution is absolutely worthwhile.

Product Embodiment

If I understood correctly, your Flood Box would be stored away and only retrieved and used when disaster hits. But I was not sure what you were trying to protect: Items like insurance documents, but also valuables (that some people might not trust a bank to store safely, although that would seem like a good place to do so) should be ticked away in water- and fireproof container at any time - since trying to do so when panic sets in might make quick evacuation harder. And how would this box be superior to any existing container like - for example - a cooler? Creating a tight seal with a lid on an collapsible container seems daunting, at best.

Model Learnings

You certainly showed that it is possible to collapse an deploy a foldable storage box. But that should not have come as a surprise, since collapsible boxes are already in wide use. Before you go further with this idea, start looking into the challenge of making such an inherently compliant structure rigid enough to form that tight seal that seems to be the central value proposition of your solution.

Model Execution

See my previous comment.

James Penn

Product Opportunity

I'm not quite sure about the need here. I would be interested to hear from users regarding what possessions they would be putting inside such a product before deciding if this is the best approach, or if instead they should just be storing those possessions in watertight containers in the first place, for example.

Product Embodiment

No feedback provided

Model Learnings

No feedback provided

Model Execution

No feedback provided

Rob Podoloff

Product Opportunity

Certainly a timely concept given recent events in Florida! However, I am not clear on the type of items that this is intended to protect. Wouldn't you keep important papers, etc. in waterproof containers anyway if you live in a flood prone environment. What type of items do you invision your product being especially well suited for?

Product Embodiment

see above

Model Learnings

No feedback provided

Model Execution

No feedback provided

Kaitlyn Becker

Product Opportunity

Gold team - all great presentations - good job practicing and prepping for these. I'm still not convinced of the need and full motivation of this product over other valuable products, although the team directly addressed other products on the market.

Product Embodiment

As mentioned above, I'm not convinced that there is a need for this product over dry bags, which seem like an easier format to produce in various sizes and store in a collapsed state.

Model Learnings

The team mentioned that the need for this product related to the available sizes. It would be good to talk about what would necessitate a larger container, why, and how big. Why does this need to be a box over a bag? Is this something you use when a flood is coming or something you store items in all of the time so they're already protected if you're surprised by flooding? Does this need to float or stay anchored? Is there a way to track it down if it floats away?

Model Execution

I think user need and use case could have been more fully explained/explored. What are the hardest challenges - deployment? maintaining a seal?